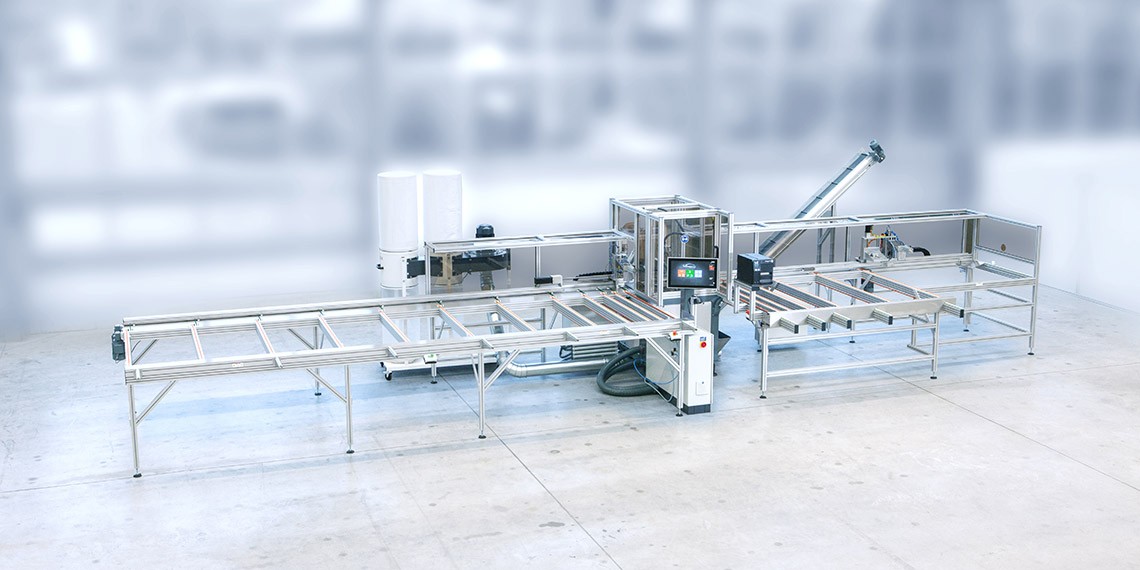

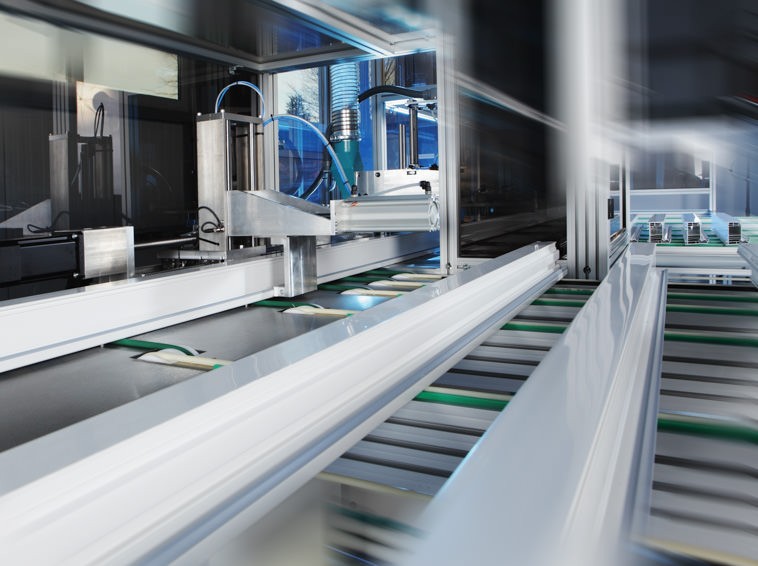

Our Profile Cutting Centre – Maximum output. Minimum waste.

Our Cutting Centre ASZ for windows and outer door profiles meets the specifications of our customers: high dimensional accuracy, optimum material yield, long service life, easy access to all essential units, simple operation and economical use of the material used.

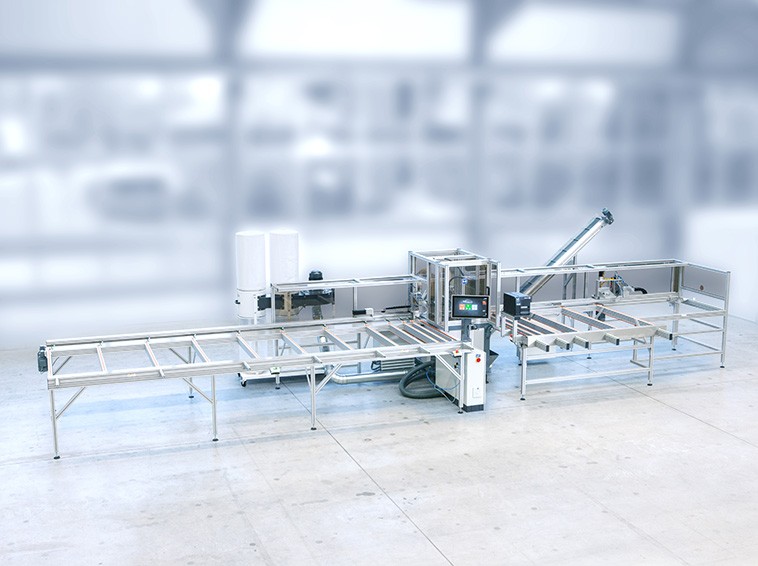

The Cutting Centre is constructed in a modular design and in such a way that it can be accessed from all sides. Quick saw blade swapping, ease of maintenance and a control unit with a clear layout, touch-screen monitor-led user guidance, scanners as well as in-feed and removal buffers are among the key features. Thanks to freely programmable tong positions, each profile cut can be machined without any time being needed for retooling. The Cutting Centre saw head is freely programmable from 22.5° to 157.5°. This means top quality and optimum dimensional accuracy.

Our machines are delivered fully equipped. Furthermore each machine is individually manufactured by us and adapted to the specific requirements of each customer.

Our Cutting Centre is the ideal accompaniment to our Profile Machining Centre.

Cutting Centre

Download cut diagram

Control system

- Plain text operation in your language on the 15“ touch-screen monitor

- Control via a diskless industrial PC

- Freely-programmable tong positions allow profile cross-sections to be cut without any time needed for retooling

- Datasets from window construction programs are scanned in on an order-specific basis and the profile data displayed visually

- Fault diagnosis with detailed graphic display on the monitor

- Fault diagnosis and software maintenance online / integrated remote maintenance software

- Cutting Centre saw head freely programmable within a range of 22.5° to 157.5°

- Positioning of the profile bars in longitudinal direction via two program-controlled servo axes

- Actuation via a three-phase motor at 2.2 kW and 2,800 rpm.

- Minimum cut length is 200 mm (inner dimension), the maximum cut length is optional

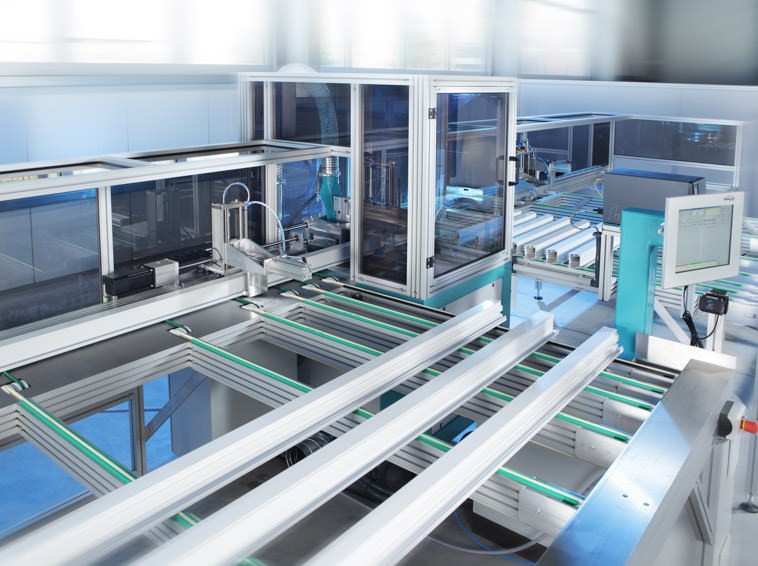

The result

- Optimised material consumption and reduced manufacturing costs thanks to minimal waste

- Reusable leftover pieces are labelled with the printed stickers and registered by the scanner for further use.

- Integrated leftover piece evaluation

- Proven ease of handling

- An investment that will pay off for your business

- Benefit from our many years of experience